-

Materials

Rattan skin

Rattan is a natural material that grows in the Far East and is shipped to us after a rigorous selection so that we can use it to manufacture our furniture.

It’s characteristics are elasticity, flexibilityand lightness. It is hand woven and curved by the skillful hands of our highly specialized artisans who turn raw natural material into elegant design furniture. It is this skillful workmanship that makes our piece extremely lasting in time. From the raw rattan cane several materials can be extracted through different manufacturing operations.

-

Materials

Rattan without skin

Rattan is a natural material that grows in the Far East and is shipped to us after a rigorous selection so that we can use it to manufacture our furniture.

It’s characteristics are elasticity, flexibility and lightness. It is hand woven and curved by the skillful hands of our highly specialized artisans who turn raw natural material into elegant design furniture. It is this skillful workmanship that makes our piece extremely lasting in time.

.jpg)

-

Materials

Rattan / Anilin finishing

Rattan is a natural material that grows in the Far East and is shipped to us after a rigorous selection so that we can use it to manufacture our furniture.

It’s characteristics are elasticity, flexibility and lightness. It is hand woven and curved by the skillful hands of our highly specialized artisans who turn raw natural material into elegant design furniture. It is this skillful workmanship that makes our piece extremely lasting in time.

-

Materials

Pulut

Is a twith skin variety of the larger rattan cane, it has a reddish warm colour and it is used in its entirety. As the rattan cane with skin it cannot be anilin stained.

-

Materials

Rattan-core natural

During the extraction by draw process rattan-core is obtained in different diameters or in a flat-oval section. Once soaked in water it can be woven into an endless variety of patterns.

-

Materials

Rattan-core / Anilin finishing

During the extraction by draw process rattan-core is obtained in different diameters or in a flat-oval section. Once soaked in water it can be woven into an endless variety of patterns, and can be anilin stained in any color.

-

Materials

Rattan-core / Lacquered finishing

During the extraction by draw process rattan-core is obtained in different diameters or in a flat-oval section. Once soaked in water it can be woven into an endless variety of patterns, and can be lacquered in any color.

-

Materials

Wood

The used wood species: Beech, Oak, Walnut quality “Canaletto”, come from controlled plantation under surveillance of the concerned monitoring organizations and thus respecting the ecological standards.

-

Materials

Outdoor wood

Iroko’s wood has a yellow-straw color that tends to oxidize with ease, assuming a brown-gray tonal uniform. It is an easy wood to work, despite its considerable hardness, which makes Iroko a timber destined to last over time. Iroko has good thermal stability for this reason it is an excellent outdoor wood in damp environments.

.jpg)

-

Materials

Rolon

Extruded GH-AVV thermoplastic material reinforced with a Nylon thread that provides constant elasticity, morphological stability, and comfortable sitting. Non-toxic and washable, ROLON is suitable for both INDOOR and OUTDOOR use.

-

Materials

Leather cord

The leather cord is a natural material of great resistance and is treated following the traditional methods of vegetable-tanning. It is then cut, given its round shape and waxed. A fixative finishing is then applied in order to make it more resistant and enhance the aesthetic characteristics.

-

Materials

Bopifil

A rigid extruded profile made from paste-dyed thermoplastic material. It’s a high-performance material in terms of resistance to UV rays and weathering. Non-toxic and non-polluting, it’s suitable for both INDOOR and OUTDOOR use.

.jpg)

-

Materials

Polypeel

Is a mass dyed synthetic fibers: this means that the color is not only on the surface and so the color doesn’t fade away. It is derived from polyethylene through an extrusion process and have high performance characteristics such as resistance to UV rays and bad weather and durability in time. It is recyclable, they don’t absorb sunscreens or suntan oils, it is washable with water and neutral/non abrasive soap and resistant to fungal growth, mould and insects.

-

Materials

Polycore

Is a mass dyed synthetic fibers: this means that the color is not only on the surface and so the color doesn’t fade away. It is derived from polyethylene through an extrusion process and have high performance characteristics such as resistance to UV rays and bad weather and durability in time. It is recyclable, they don’t absorb sunscreens or suntan oils, it is washable with water and neutral/non abrasive soap and resistant to fungal growth, mould and insects.

-

Materials

Gres porcellanato

A material obtained by mixing natural raw materials, using environmentally-friendly production techniques. Thanks to its advanced mechanical performance and resistance, it finds a place in both architecture and design. The glossy surface finish emphasizes the veins, which faithfully resemble those of NERO MARQUINIA and CALACATTA marble.

-

Materials

Metallo Verniciato

Le strutture in acciaio vengono verniciate per renderle perfettamente adatta all'outdoor.

-

Materials

Ardesia stone - Dorada stone

A thin, lightweight, and flexible sheet of natural stone, obtained from slate and quartzite. Reinforced with fiberglass and resin, this material is applied to a rigid backing to create the tops of our tables, forming a water-repellent, ecological, and non-toxic surface. Easy to wash with neutral products, natural stone features variations in color and veins.

-

Materials

Fabrics

-

Materials

Avonite

-

Processing

Bending

Rattan is the general term to define this material while “giunco” is the italian translation. There are over 100 varietes of rattan, but the most used are: Manila, Manau, Malacca, Palasan. The rattan cane is manually heated over an open flame and curved. The use of the flame allows a total freedom in terms of shapes and as a consequence in the design of the furniture.

.jpg)

-

Processing

Weaving

The rattan core threads, which are then hand woven, come from the the inner part of the cane, they are obtained in different sizes by the use of a special machine. To be woven the rattan core threads must first be soaked in water, so that they can become flexible enough to be hand woven. The natural color of the rattan cane core is very pale, and the lightness of this color is guarantee of its quality: the more pale it is the higher the quality. As time goes by and depending on the amount of light to which it is exposed the natural rattan core and core threads will turn into a warm honey colour which as well is a sign of a high quality material.

-

Processing

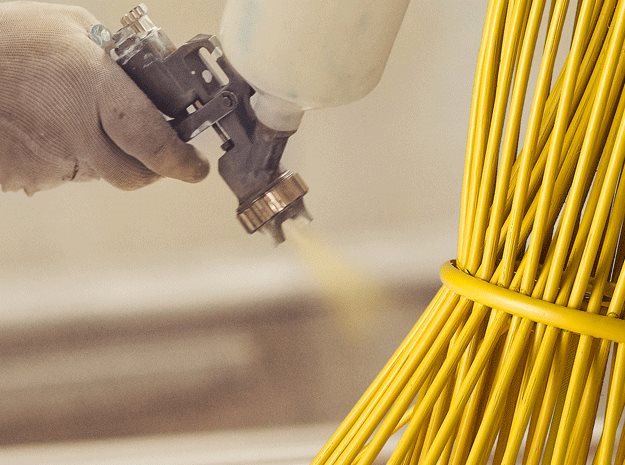

Colouring

Once the piece of furniture is completed it can either be left raw or undergo the staining or lacquering phase. Anilin stains are water based finisheswhich are completely natural and while colouring the material they are very light and allow to still see the vaining of the material. Alternatively a lacquer finish is another option.

-

Processing

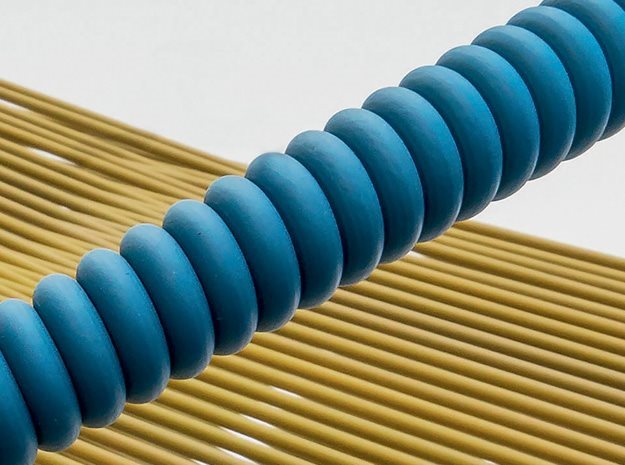

Bindings

Canes are assembled with screws and nails in order to make the piece of furniture stable and resistant. The bindings have the double function of reinforcing and covering the head of the nails. Occasionally the bindings can be also a decoration of the furniture itself. The materials used for this purpose are leather, flat-oval rattan core threads and flat-oval rattan skin threads.

Materials and workmanship

Filter

All

Materials

Processing

Downloads